From Idea to Reality – Your Trusted Partner for Premium Packaging Solutions

At Guangxi Yingmei Packaging Products Co., Ltd., we take pride in crafting custom aluminum tins that not only protect your products but also elevate your brand. Whether you’re in the cosmetics, food, healthcare, or specialty goods industry, our tins offer durability, style, and functionality. In this blog, we’ll walk you through our step-by-step process for creating the perfect custom aluminum tin—and show you why so many businesses trust us for their packaging needs.

Step 1: Understanding Your Needs

Every great product starts with a conversation. We begin by listening to your requirements: the size, shape, design, and purpose of your aluminum tin. Do you need a sleek, minimalist container for luxury cosmetics? Or a sturdy, resealable tin for food products? We ask detailed questions to ensure we fully understand your vision.

Furthermore, we consider your target audience and brand identity. This helps us suggest the best options for material thickness, coating, and finishing.

Step 2: Design & Prototyping

Once we have a clear idea, our design team gets to work. Using advanced software, we create 2D and 3D models of your custom tin. This allows you to visualize the product before it goes into production.

Meanwhile, we also provide material samples and color matching services. You can touch and feel the quality of the aluminum and choose from a variety of finishes—glossy, matte, metallic, or textured.

After finalizing the design, we produce a prototype. This sample tin is shipped to you for approval. We want to make sure you’re completely satisfied before moving forward.

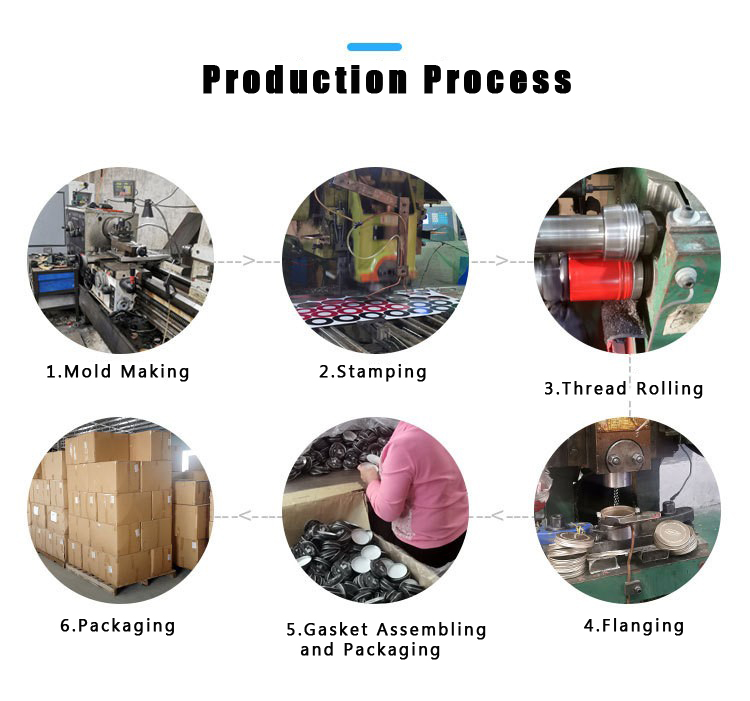

Step 3: Tooling & Manufacturing

With your approval, we move into the manufacturing phase. Our factory is equipped with modern machinery and staffed by experienced technicians. We use high-grade aluminum that is lightweight, recyclable, and resistant to corrosion.

We can produce tins in various shapes and sizes. We can add features like hinged lids, embossed logos, or printed designs. We can also incorporate liners for added product protection.

Throughout production, we conduct quality checks to ensure every tin meets our standards.

Step 4: Decoration & Finishing

This is where your tin truly comes to life. We offer multiple decoration options:

- Printing: High-resolution offset or digital printing for vibrant colors and sharp details.

- Embossing/Debossing: Create raised or recessed designs for a tactile experience.

- Labeling: Apply paper or plastic labels if preferred.

Your logo and branding elements are applied with precision to enhance visual appeal.

Step 5: Quality Assurance & Delivery

Before shipping, every tin is inspected for defects. We test for durability, leak resistance (if applicable), and overall finish. Once approved, we carefully pack your order and ship it worldwide.

Why Choose Us?

- Experience: We’ve served clients across industries for years.

- Customization: From size to decoration, we offer endless possibilities.

- Eco-Friendly: Aluminum is recyclable, and we promote sustainable practices.

- Competitive Pricing: High quality doesn’t have to mean high cost.

Explore Our Products

Ready to create your own custom aluminum tins? Browse our Aluminum Tin Collection to see examples or request a quote.

Follow us on social media for more packaging inspiration and updates:

Facebook | TikTok | 인스타그램 | YouTube

Let’s bring your packaging ideas to life! Send your inquiry to us today to get started.